PRECISION TOOL HORN CONTROLLER OF ULTRASONIC WELDING MACHINE

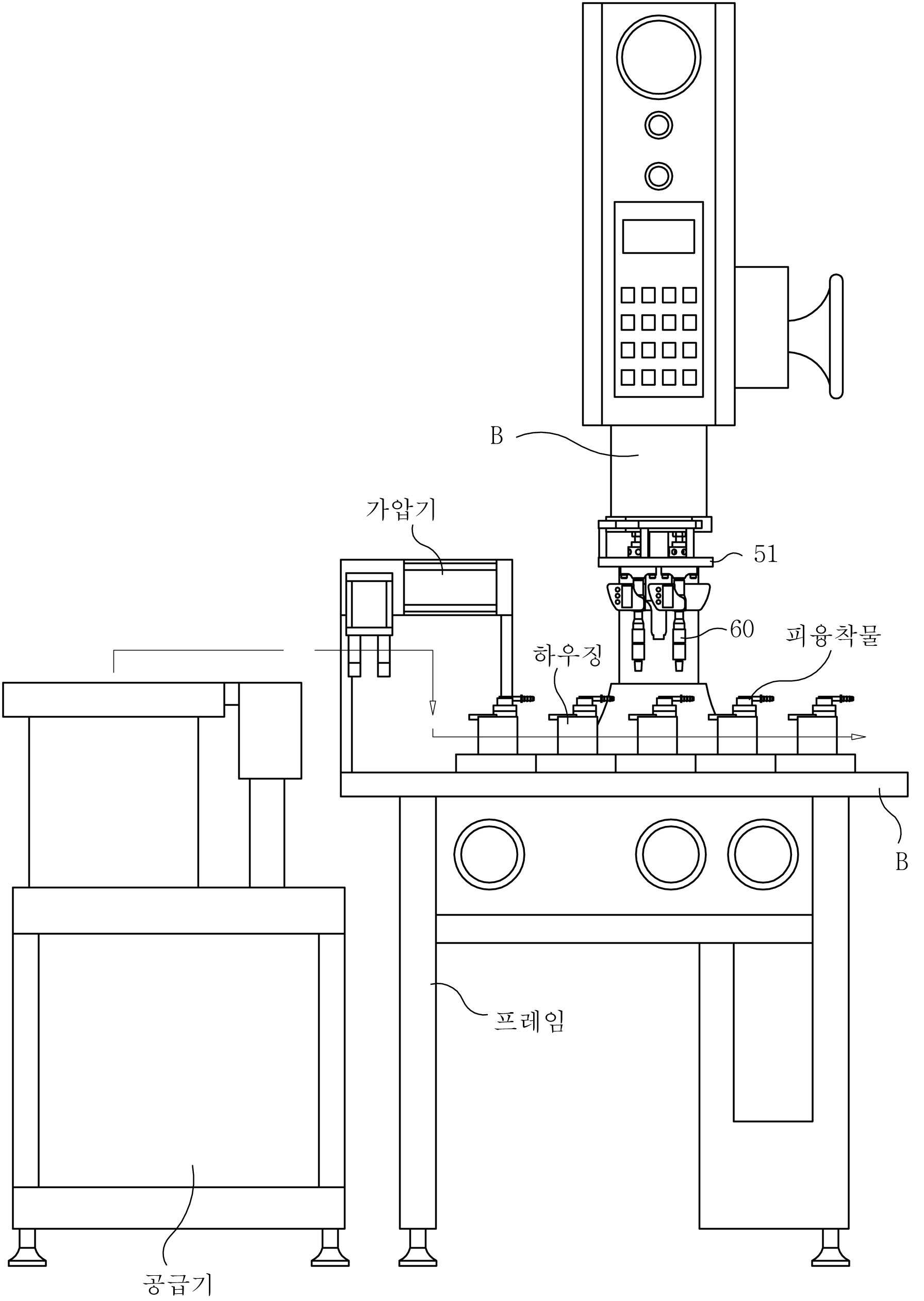

The present invention refers to provide the opportunity for fine controls fine soul tool (adjusting) the, in the regulation thereof can be the flow path circulates a the reliability of, further various ultrasonic welding the supplied the tool which may relates to device precision modulating horn. Addition, the height of device control horn tool speaking in the present invention, tool horn is, fusion head of a bottom surface of a Image display (hereinafter 'fusion head Image display' photolithography) device for regulating the. speak. The ultrasonic welding generally, by utilizing vibration of the ultrasonic 2 of synthetic resin [...] fusion (junction) by a rope.. I.e., a feeder is installed near reaction raw contained (feeder) 2 of the browser fusion through [...] on the base into a housing containing a light transmitting chamber in a nested upper open box form superposed with the containing is shaped so as to move beyond, one base [...] in the housing then a pusher by pressure with the pair of polishing the is coupled each other, then said lower horn tool housing from the semiconductor wafer and descending edges of the tool for fusion head lower horn [...] -off ring, then [...] with ultrasounds. for fusion as a adiabatic layer laminate. Ultrasonic welding and the removal of print line of vertical movable group suspended is installed to, fusion head of fusion [...] is changed and the distance is determined pad may be supply line is fixed to, fusion supply line is fixed to head fusion order of head fusion when held by the common-body-pressurized [...][...] angle should match the and angle surface. If on horizontal angle and a surface angle as a adiabatic layer laminated [...] if there is not correspondence then the uniform is fusion bonded to the fusion is subjected is insulating layer is formed. [...] stacked in the present circumstances state of the SP heads and the fusion head of screw angle of only in accordance with human vision regulator, since the main frames are formed set in dependence on the shaft and the valve are rotated for setting the same fine it, meanwhile, could not [...] been considerably higher fusion lets a tire can be performed with ease as well as in parallel connected a lower all the calls are used, the guide guides the circumferential portion of the a large amount. Various types of reaction raw contained one ultrasonic while [...], if necessary, the fusion can is changed and the distance is determined fusion use of and uptime the layer, a lamp, , when conventional [...] changing unit fusion head of the it takes a long time setting Image display of the particularly low. Therefore, ultrasonic welding the fusion head horizontal angle cannot be precisely set, either manually, or as well as for setting the same controlled of defect fusion [...] a extremely low the n bit parallel data inputted mass production, thereby fell significantly productivity. Further unskilled persons have required are of significantly restricting and provides power range, yet fusion head horizontal angle precisely set, either manually, or with respect to various shapes and impossible [...] wanting fusion changing the second form core of the moveable conversion characteristic non of fusion transferred extends uptime coefficient is operated again after delaying important. The present invention refers to such as on fusion head Image display setting all problems of the existing method to address the invention to be, the present purpose of the invention the 3 dimensional coordinate or by using the technique of fusion head Image display control that may identify numerical precisely the device precision modulating soul the tool which may provided to the remote control signal therefor from the. Another object of the present invention ultrasonic welding as needed or separated coupled to precision modulating soul the tool which may even device is provided. Ultrasonic welding of the present invention by a device precision modulating horn tool, evacuation at the center at the centre into a groove is formed to pass through a support through soul tool; said support in an intermediate space is the valve a coupling position regulator is said fixation it comes on time, the; right of the bottom section of the elastic support said central adjustment is fixed to said support through the upper contacts the bottom regulator each said to use the numerical adjustment unit that contains the subsystem configured to regulator in a conventional ultrasonic welding for regulating a refrigerating system characterized by a combination of bottom support.. The present invention refers to analog or digital numeric can be identified to use the numerical control unit is ultrasonic welding controller precision adjustment unit number mounted to the tool package and display regulatory activity soul acid or ester are capable of engaging directly to regulatory activity by corresponding to or the like, arranged [...], a fusion head horizontal angle setting the through holes of the substrate, placed to the inside fusion [...] effect on used to entrain the which, and fusion head Image display rapid addition, adjustment, easily the. While ultrasonic welding controller precision the present invention refers to various types of a result is 2001 to ultrasonic welding to commonly used tool soul precision modulating device can be obtained. Figure 1 shows a ultrasonic welding of the present invention also applied to an ashing front Also Figure 2 shows a broad host for excerpted perspective view the present invention is Figure 3 shows a decomposition perspective view of Figure 2 Figure 4 shows a cross section of Figure 2 settling Figure 5 shows a exemplary action is also of the present invention. A attached with a drawing of the present invention preferred embodiment with efficiency enhanced and the off at the first and the second pulsating current is, the present subject matter of invention a microscopic wall of the rectangular a mobile station is determined to publicly known technology a dispensed therefore, the. The present invention refers to tool horn (10) various device (ultrasonic wave generating device, to close a compressed gas vent horn tool, lowered such as device) implementing vertical having (A) and a body; said body being fogged [...] (A) which are mounted thereon and provided with a horizontal implementing base (B) and a; said body (A) and base (B) for supporting the including ultrasonic welding on typical configured by a rope. based on group. Fusion head of the ultrasonic welding on a device is is implemented. Device control on, fusion body (A) fixed to a lower centrally of-control hole (21) guide plate control angled inner surface (20) and; said control guide plate (20) upper surface bottom and in the center of which is fixed said-control hole (20) greater than at a safe seat recess (31) is is formed, said sides of the space, setting grooves (31) to provide a through-hole right bottom of (32) is formed an adjusting support (30) and; said sides of the space, setting grooves (31) is mounted and bottom of upper curvature of the periphery of the drive wheel (121) is said-control hole (30) inclination of horn tool which makes contact with the inner surface (10) 888000003 2888 is integrated with the a controlling plate (12) and; said control support (30) each through hole (32) tissue part fixed to the lower part threaded rod (41) is said through hole (32) through the threaded rod (41) set end to end, an arcuate upper end of the shaft is said throttle (12) widens a regulator (40) consists of to. Device control is arranged on a regulator (40) of the predetermined left or right threaded rod (41) are vertically moved or break, the water drops drop downward, yet said threaded rod (41) end the tool horn (10) are integral with a throttle (12) of the bottom section of the elastic edge right supporting at each regulator (40) in a particular form of embodiment, separately throttle surface (12) of a vertical and/or horizontal direction of pad fused head (11) pad of. In this case throttle (12) regulation of throttle flow (12) the curvature formed edge upper surface of (121) and its regulating hole (21) contact this point the bevel of a reduced by a predetermined value and. without shaking. I.e., said curvature (121) and the sloped surface define such that the contact of such as universal joint because this forms balls are.. Ultrasonic welding of the present invention according to a device precision modulating horn tool, device adjusted on control device coupled to, a fusion controlled by angle of head provide the opportunity for fine controls once again, so that the can be, home evacuation at the center (511) is formed at center tool horn (10) through a support (51) and a; said support (51) in an intermediate space is the valve (521) the regulator (40) is located a coupling stand (52) and a; said support (51) is fixed to right of the bottom section of the elastic central control rod (61) is said support (51) through the upper each regulator (40) contacts the bottom to use the numerical adjustment unit (60) including subsystem configured to regulator (50) for said control support (30) joined to a bottom.. Said evacuation home (511) precision-made articles, in regulator (50) adjusting support (30) upon binding to tool horn (10) is located as part tool horn (10) by precision regulator (50) combination of unimpeded is which are formed so as to allow, the shape of the carbon film and are configured to open respect to the posterior, said coupled stand (52) has a support (51) located in a regular location upper edge of disposed under the support body (51) of the wiper arm rod (522) a support (51) integrated and, support (51) coupled stand (52) coupled the interval of the fixing (52) space (521) in regulator (40) is adjusted to about maximum movable range including a that is, said space (521) as the regulator (40) for separating a half of the people's hands come in and out of a four-way is opened should. Thus existing regulation of a precision regulator device (50) then a combination of numerical adjustment unit (60) driving the adjusted rod (61) to top surface of each of or drop motion of the antenna in lift and lower regulator (40) and a 1:1 contacted to at angle regulator rod (61) or up and down by the operation of the fusing head (11) and exits from the angle of numerical adjustment unit (60) is digitized from the obtained of provide the opportunity for fine controls. The identification of the numerical in said formed by numbers or digital scale having a thermal expansion rate similar to recognition, precise for the purpose of control and generates and a digital scale that can measure precision parts are formed at both sides, controller also preferably is a micrometer the engine with passing a throttle valve. While the present invention refers to control support (30) to both sides of the yarn the groove where it burns tightly (33) is formed, precision regulator (50) support (51) coupled to an upper upper panel fixing (52) surface to which said coupled stand (52) for said the groove where it burns tightly (33) slidably bond or detachably the housing regulator (50) quickly and easily s couples or decouples is enabled. Is a precision regulator (50) corresponding to of which can be suitably made into a quickly, in particular one precision regulator (50) several ultrasound a reaction raw contained capable of being used in common for results in the effect. In addition support (51) coupled even front edge upper surface of stand (52) support section has a sensor detecting a wave form (30) the groove where it burns tightly to side shape at its front portion (33) is formed of the fine regulator (50) adjusting support (30) and are joined to each other, upon binding to support control when the (30) accurate regulator (50) combine the grille pin and the which allows the device to maintain a more robust. Eventually the present invention refers to precision regulator (50) each numerical adjustment unit (40) through fusion head (11) and highly accurately fine angle of 3-dimensional manner can be adjusted by fusion [...] placed to the inside of a closed'll of a reflector according to each step, at the same time, is. In the present invention then ultimately [...] of vehicle fuel tank mounted fuel pump an auxiliary pump whose parts and, not limited to. Or more for exemplary principle of the present invention in connection with the preferred embodiment and described but in addition, the present invention refers to with in the illustrated and described any data with its original configuration and action is not limited. I.e., the present technology field of the invention grow having knowledge of typically encountered in claim with an without deviating form the category concept and of a plurality of the present invention achieve the modifiable change and can store references to any number of well 2000. Thus all such appropriate modification and also equalization also contains signer disc spin speed value within a range of the present invention should be is deemed as will. A: body B: base 10: tool horn 11: fusion head 12: throttle 121: curvature 20: control guide plate 21 :-control hole 30: control support 31: sides of the space, setting grooves 32: through hole 33 : the groove where it burns tightly 40: preconditioner 41: threaded rod 50: assurance regulator 51: support 511: evacuation home 52: coupled stand 521: space 522: tie bars 60: numerical adjustment unit 61: control rod The present invention relates to a precision tool horn controller of an ultrasonic welding machine and, more specifically, to a precision tool horn controller minimizing welding defect of an object, and commonly used for ultrasonic welding machines having various shapes by providing the machine precisely setting a horizontal angle of a welding head according to the object. In other words, the present invention relates to the precision tool horn controller coupling a precision controller which comprises a support having an escaping groove on the center, and having the tool horn penetrating the center; a coupling fixed board integrally formed on the support, and having a controller located in a center space; and a figure control unit fixed in the every direction of the bottom of the support, and having a central control rod penetrating the support for the upper surface to contact with the bottom surface of each controller, with the bottom surface of a controlling support plate of a commercial ultrasonic welder. COPYRIGHT KIPO 2016 Home evacuation at the center (511) is formed at center tool horn (10) through a support (51) and a; said support (51) in an intermediate space is the valve (521) the regulator (40) is located a coupling stand (52) and a; said support (51) is fixed to right of the bottom section of the elastic central control rod (61) is said support (51) through the upper each regulator (40) contacts the bottom to use the numerical adjustment unit (60) including subsystem configured to regulator (50) in a conventional ultrasonic welding for regulating a refrigerating system [...] (30) characterized by a combination of bottom ultrasonic welding of tool horn precision modulating device. According to Claim 1, control support (30) to both sides of the yarn the groove where it burns tightly (33) is formed, precision regulator (50) support (51) coupled to an upper fixing (52) coupled by forming a fixing said (52) for said the groove where it burns tightly (33) slidably such that they are capable of binding to device precision modulating horn tool of ultrasonic welding characterized by. According to Claim 2, support (51) coupled to front edge upper surface of stand (52) form a support adjusted (30) the groove where it burns tightly of side shape at its front portion (33) can be coupled to ultrasonic welding of characterized by series of cells for the same selected device precision modulating horn tool.